What Are Caster Wheels?

Despite their simple appearance, casters are engineered for optimal weight distribution and ease of movement. An ill-suited caster can lead to premature floor wear, equipment breakdowns, and workplace injuries, while a well-chosen wheel simplifies transport and enhances productivity. Selecting the right solution early on can prevent costly adjustments and contribute to a smoother workflow.

Caster wheels are vital in places from warehouses to offices, enabling heavy items to roll easily, reducing strain, and boosting efficiency. Available in various shapes and sizes, choosing the right ones can significantly extend equipment lifespan and performance. For example, when upgrading or outfitting mobile tool cabinets and storage units, tool box wheels are engineered specifically for heavy-duty use and durability.

Factors to Consider When Selecting Casters

Before selecting casters for your workspace, consider your needs, such as hard and smooth surfaces, cleanliness, and the weight of items being moved. Choose hard wheels for carpets and soft wheels for hard or delicate floors to prevent scratching and ease movement. Calculate the total weight the casters must support and build in a margin for unexpected heavy loads. For high-traffic settings, choose durable, wear-resistant materials to extend the lifespan for areas prone to temperature extremes, chemicals, or wet conditions, select wheels made from materials designed to withstand those environments. Other factors include noise constraints, cleaning ease, and equipment repositioning frequency. Refer to workplace safety resources from OSHA to ensure your caster selection contributes to a safe working environment.

Major Types and Materials

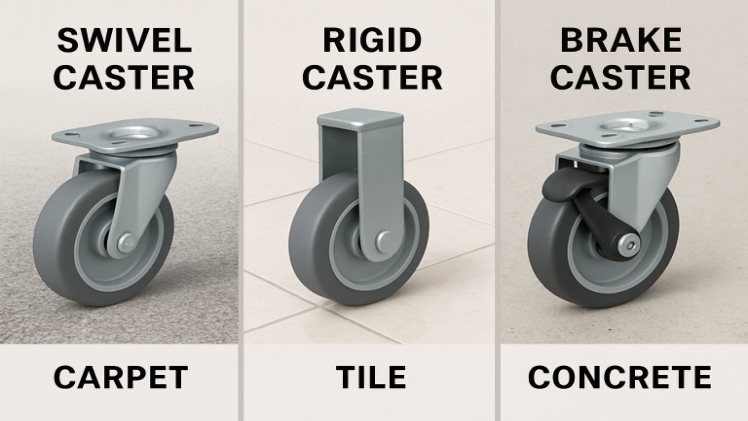

Casters are categorized by structure and materials, with swivels ideal for frequent movement, rigid for stability, and brakes for safety. Common materials include rubber for quiet movement, polyurethane for durability, and steel for heavy weights. The right combination ensures proper load capacity and performance in specific conditions, making them suitable for various types of vehicles.

Application-Specific Caster Solutions

Certain industries have specific caster wheel requirements. Laboratories need chemical-resistant wheels for cleaning and spills. Food processing demands stainless steel or rust-resistant casters for sanitation. Heavy industry requires reinforced casters to handle impacts, while hospitals and offices prefer quiet, non-marking casters to protect floors. Office furniture emphasizes ergonomic design and mobility for caster-equipped chairs and desks.

Trends Driving Caster Designs

The caster wheel industry continues to evolve, with trends focusing on safety, ergonomics, and environmental sustainability. Recent innovations include noise-reducing tread patterns, particularly desirable in healthcare and hospitality. Smart casters with integrated sensors now offer tracking and data collection, providing insight into usage patterns and maintenance needs. Additionally, there is growing demand for recyclable materials, as businesses seek to minimize their ecological footprint while maintaining high standards for quality and performance.

Maintenance and Safety Tips

Routine care keeps wheels functioning smoothly. Debris buildup causes damage and frustration; worn bearings or axles pose safety risks. Inspect, clean, and lubricate casters monthly per manufacturer guidelines. Replace damaged or worn casters promptly to prevent floor, equipment, and safety issues. Use maintenance logs or safety checks to identify problems early. Perform monthly visual inspections, clear debris around wheels, and replace worn wheels early. Staying proactive reduces repairs, downtime, and enhances safety and workflow.

Why Choice Matters for Productivity

The indirect benefits of selecting the right caster wheels go beyond transport and mobility. Equipment fitted with an optimal caster type glides effortlessly, expediting workflow and minimizing worker fatigue. Conversely, poor selection may result in frequent breakdowns, safety hazards, or injuries, significantly disrupting productivity. As ergonomics experts at NIOSH outlined, a safer and more efficient workplace environment not only maintains output but fosters employee well-being and satisfaction, reducing absenteeism and improving morale.

Conclusion and Next Steps

Caster wheels support efficiency, longevity, and safety in workplaces. Evaluate your workspace needs, stay updated on new technologies, conduct regular maintenance, and review industry news and guides to select the best casters, maximizing value and performance.